Arttystationブース+ブロワーファンセット後期

こんにちは

臭いに敏感な初心者です。

塗装は、主にアクリル筆塗装を利用して臭い大丈夫に感じられるんです

プラモデル組立時のボンドの臭い、エナメル墨線作業時シンナーの臭いのために心配でした。

複数のブースと自作の中でいくつかの会員たちのアドバイスもいただいて、悩んだ末

Arttystationブースを購入しました。

ワークスペースが狭小てブースが大きければならず、オフィスの片隅でボンドの臭い外部排出が目的だと騒音も小さくしました。

Arttystationブースが第目的にぴったりなんですよ。

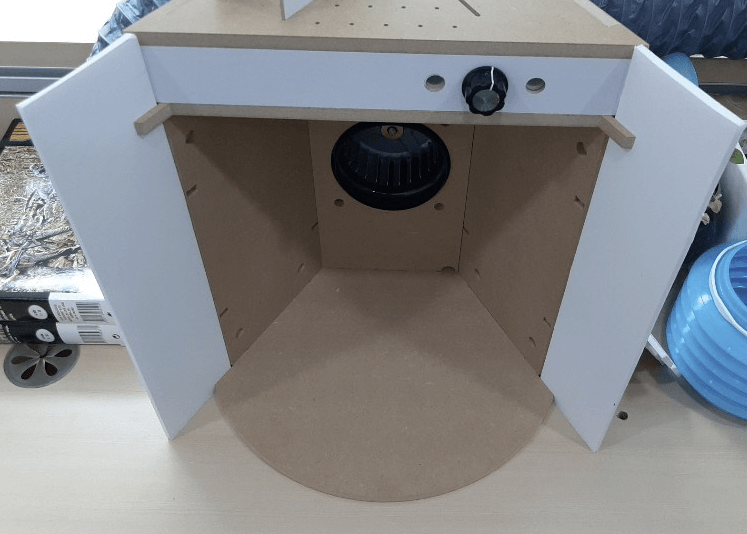

ファン速度制御のために調速機が、別に購入して設置しました。

灰色の線は、モータから出てあり、黒い線は電源です。調速機のマニュアル通りの接続してくれればされます。

モータ線の長さが余裕ていないのブース蓋を開いて作業してくれました。

運良く設置スペースがぴったりで、他工法れた桁のジョー色気調節レバーも適合

蓋をかぶせ完成した姿です。

発熱が心配されたが蓋の上部に穴が多くて大丈夫です

机の上に置いてみました。

デスク左右幅は大きいが深さが非常に短いデスクのにサイズがぴったりですね。

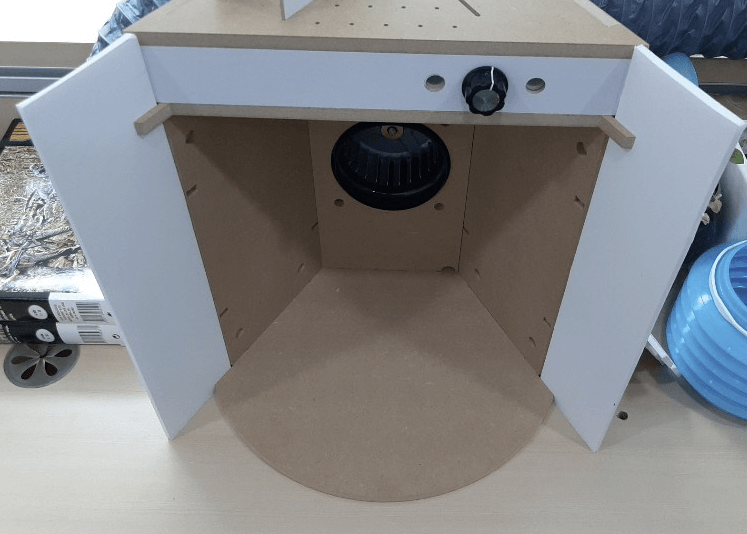

ブロワーファン組み立てた状態と、フィルタは装着していない状態です。

アクリルオプションはせず、残る発泡ボード5T建て切っ入れてきたもピッタリですね、より幅を広くしちゃってもいいようです。

オフィスの窓開けた時の基本デシベルです。

ファン速度最大時デシベルです。

ヘアドライヤー強風使用する程度の騒音です。

調速機で速度を半分減らす1メートルほど離れた空間では、ホワイトノイズ程度聞こえます。

非常に満足します。

ブロワーファンセットはファンジュルムグァンファンとジュルムグァンを締める鉄の留め具?スイッチの電源線が含まスリップ

自作ブース作成するときに最も悩みがされた他工法サイズとその他の付属を気アンソドということ良かったです。

ネジを緩めるのが難しいという指摘があったんです、

あまりにも締結がタイトになっていて、電動で解こうとしたときは空転万ながら山ナドラグヨ。

すぐに停止し、ハンドルが拳ドライバのように厚いドライバに力いっぱい与えて解放みる幸いフルましたね。

他工法た桁にファン固定する時は穴が3つなのに微合わなくて2つの締結となり、よく走っています。

ああ!そして最も重要なことは、組み立て時にゴムハンマーが必要ですよね〜

拳でウンディングするように優しく降りながら組み立ててもよいが、ゴムハンマーでので、はるかに良かったです。

調速機を設置した空間は、ボンドが必要ですが、私は調速機のためにスペースがぴったり合ってボンドを使用せずにタイトなので組み立てていた状態です。

吸引力の臭いテストはタミヤのパテでテストみました。

調速機の半分セッティングにブースの中で、パテの蓋を開けて、休止に少し絞っ置いてきた

臭いは全く出ないですね。

ブースないときパテたが匂いで死ぬと思ったブースので完全新世界ですね

残る缶スプレーもあり、後で一度テストしてみましょう。

Share post:

English

English

Korean

Korean

Italian

Italian

Spanish

Spanish